Data integration, MES/SCADA implementation, and smart monitoring dashboards.

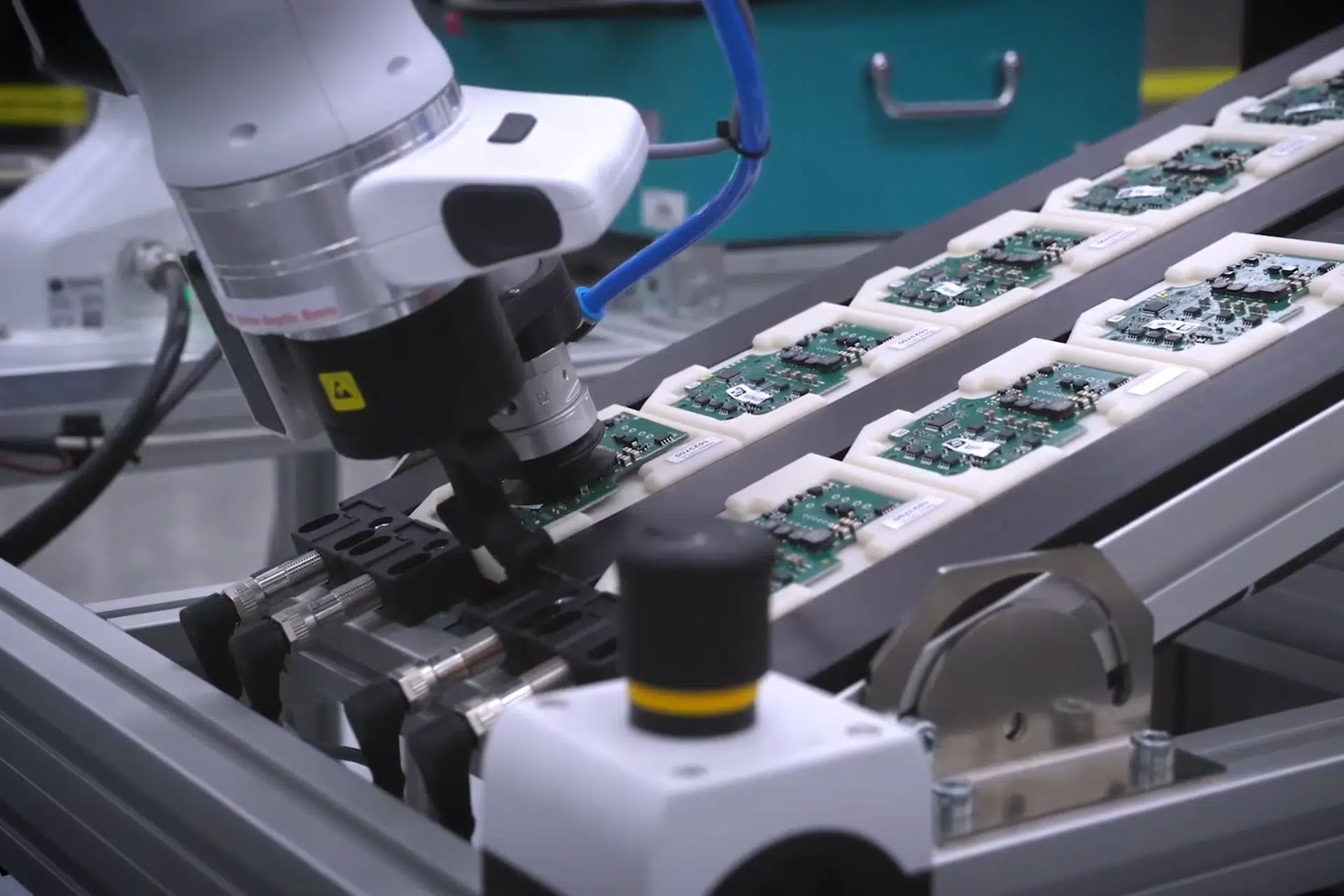

Our Digital Transformation services help you turn raw production data into actionable intelligence. By integrating machines, robots, sensors, and business systems into a connected ecosystem, we give you real-time visibility and control over your factory—so decisions are based on facts, not guesswork.

We start with data integration: connecting PLCs, robots, CNC machines, legacy controllers, and field devices into a common data layer. Using industrial protocols and gateways, we collect and normalize data from different brands and generations of equipment, eliminating silos and manual data entry. This creates a reliable foundation for analytics, reporting, and optimization.

On top of that, we design and deploy MES (Manufacturing Execution Systems) and SCADA solutions tailored to your operations. MES manages production orders, traceability, WIP, and quality, while SCADA supervises real-time equipment performance, alarms, and process values. Together, they close the loop between the shop floor and the office, ensuring that planning, production, maintenance, and quality all work from the same accurate data set.

To make this information truly useful, we build smart monitoring dashboards for leaders, engineers, and operators. These dashboards can display OEE, cycle times, downtime reasons, energy usage, scrap rates, and machine health indicators in a clear, intuitive way—accessible from control rooms, offices, or securely via web and mobile. Alerts and notifications highlight problems early, enabling faster responses and continuous improvement.

Throughout the journey, we focus on practicality and step-by-step implementation: starting with pilot areas, proving value, then scaling to full lines, plants, or multiple sites. Cybersecurity, data governance, and user training are built into the process, so your digital transformation is both robust and sustainable.

Key capabilities:

With our Digital Transformation services, your factory becomes more transparent, responsive, and intelligent—empowering your team to improve productivity, quality, and decision-making every single day.

See more solutions Contact ITS TECH