Preventive maintenance, quick-response service, component replacement.

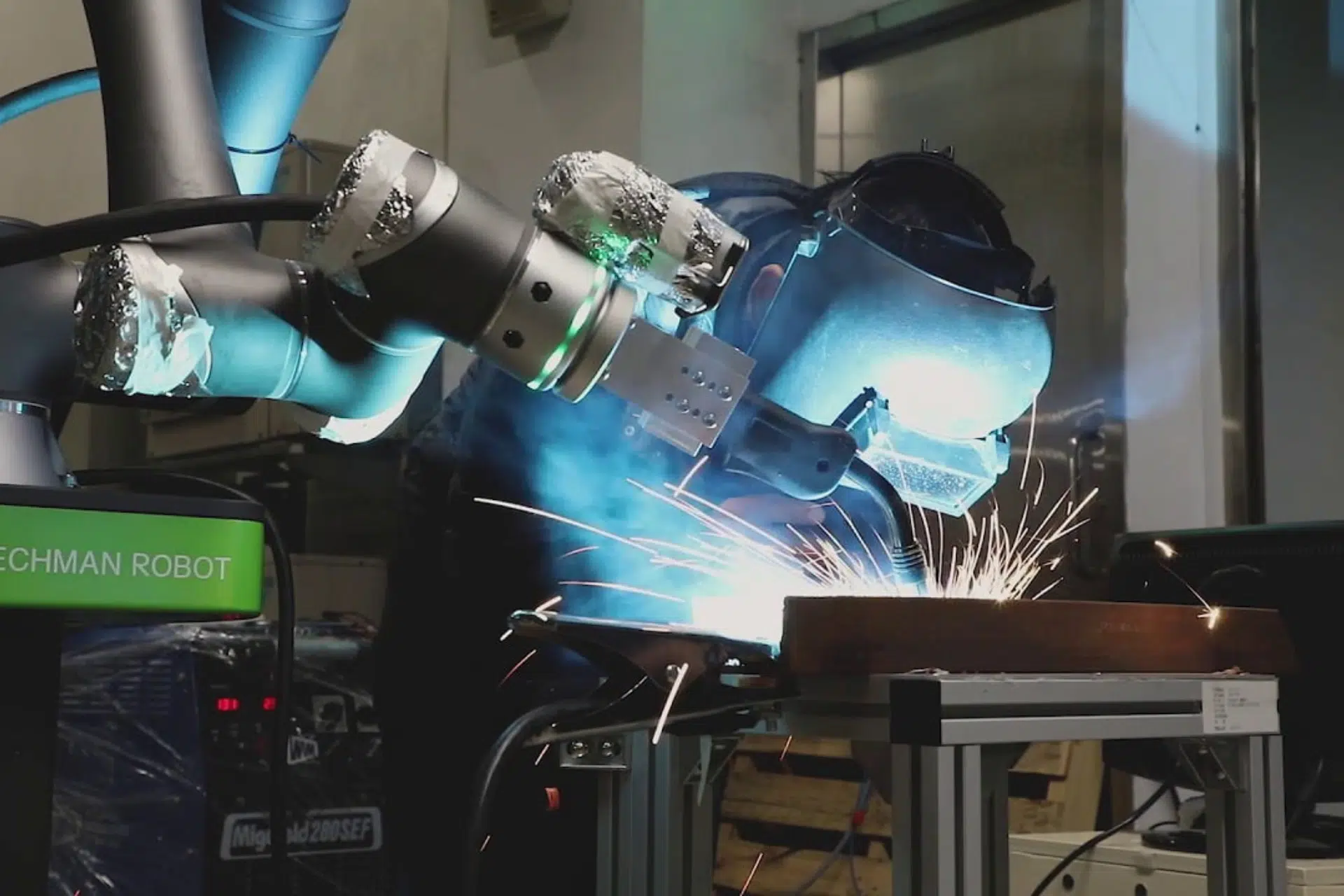

Our Maintenance & Repair services are designed to keep your automation and production systems running reliably, with minimal downtime and predictable operating costs. We combine planned preventive maintenance, quick-response troubleshooting, and professional component replacement to extend equipment life and protect your investment.

With preventive maintenance programs tailored to your specific robots, machines, and control systems, we perform regular inspections, cleaning, lubrication, calibration, and software checks according to OEM recommendations and real-world operating conditions. By detecting wear, drift, and early warning signs in advance, we help you avoid unexpected breakdowns and costly production stoppages.

When issues do occur, our quick-response service team is ready to diagnose and resolve problems efficiently—whether they are mechanical, electrical, or software-related. We use systematic fault-finding methods, backed by experience across multiple brands and platforms, to identify root causes rather than just treating symptoms. Our technicians can support you remotely or on-site, depending on the severity and urgency of the incident.

We also handle component replacement and upgrades, from robot parts (motors, reducers, cables, tools) to sensors, drives, PLC modules, and control panels. All replacement work follows strict procedures for safety, calibration, and testing, ensuring that your system returns to stable, repeatable operation. Where possible, we recommend and implement improvements that increase reliability, reduce wear, or simplify future maintenance.

Key capabilities:

With our Maintenance & Repair services, you gain a stable, predictable production environment—where equipment uptime is maximized, failures are minimized, and your team can focus on output rather than firefighting.

See more solutions Contact ITS TECH